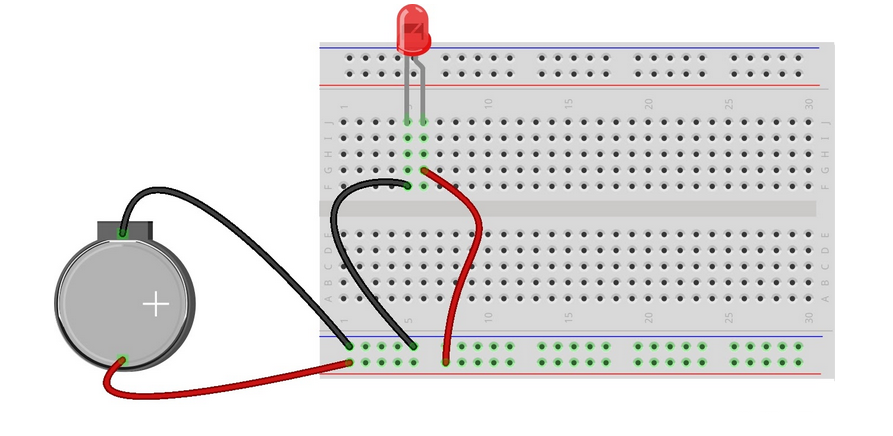

Used by hobbyists and professional engineers alike, breadboards allow us to quickly build all sorts of circuits! Breadboards got their name because in a time long ago, engineers used to use wooden cutting boards! They would hammer in nails and… Read more