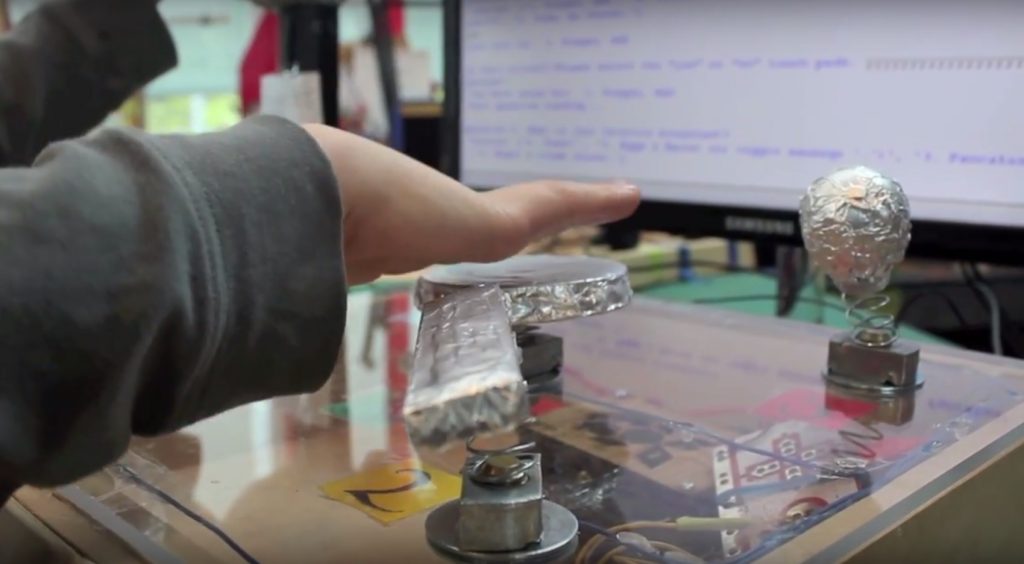

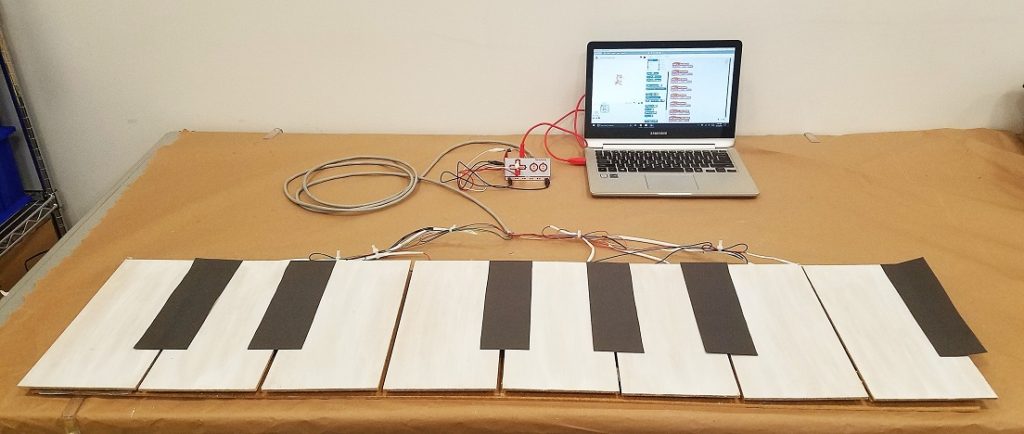

The household floor piano is a dream no more! The Makey Makey microcontroller makes it super easy (and affordable) to build your very own “foot-strument” out of common household materials. Grab a Makey Makey kit, some cardboard, and your musician shoes… Read more