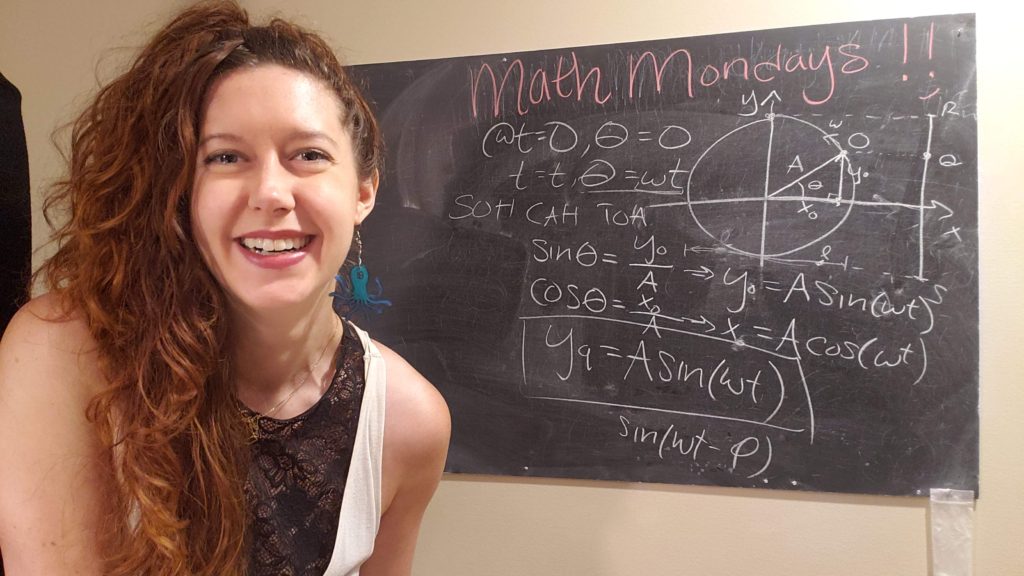

I run a YouTube channel with plethora of nerdy videos about science, technology, engineering, and mathematics, or STEM for short. It is my goal to make these subjects fun, accessible, and normalized for women and gender non-conforming folks. As a… Read more