Hello to our Maker friends in the Midwest! We are so excited that our founder/CEO, Jen Foxbot, is a featured speaker at the Ann Arbor Creativity and Making Expo on May 19th! Fox will be doing a live demo involving… Read more

Tag: maker

Make a Light-Up Holiday Card!

Light-up cards incorporate two of the best worlds of making (electronics and crafts) with the added bonus of making somebody smile. Heck yes! Here’s my approach to light-up cards and my favorite recent discoveries: pop-ups and cotton balls. Read time:… Read more

IoT Industrial Scale!

What does a baby elephant weigh?* How much impact force does a jump have?? How can you tell if a rain barrel is full without looking inside??? Answer all these questions and more by building your very own Internet… Read more

How to Use (and Choose) a Multimeter!

Checking your car battery life, debugging circuits, and finding that pesky short are all super useful functions that can be performed with just one awesome tool: the multimeter! First of all, what the heck is a multimeter?? Excellent setup question!… Read more

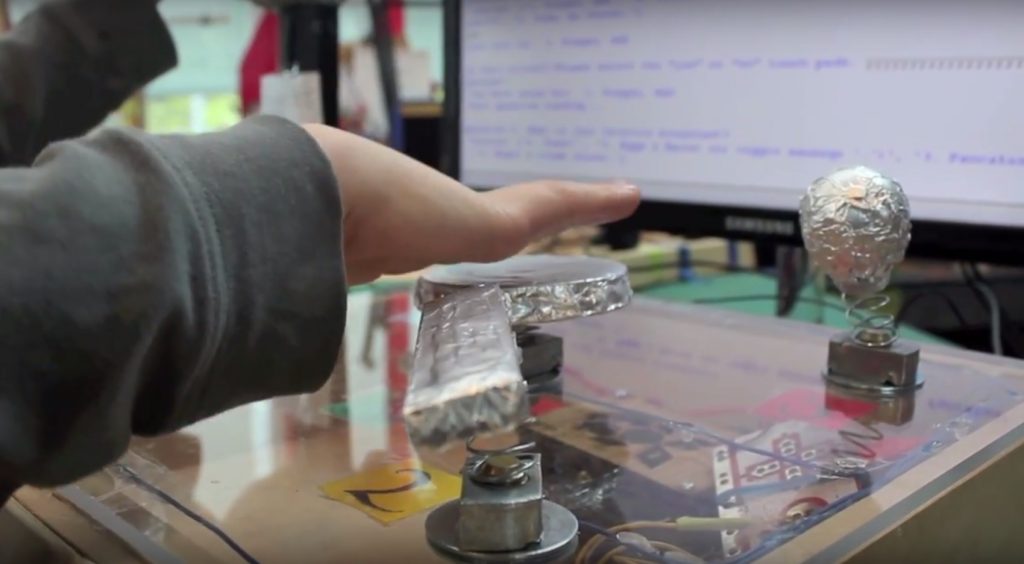

Interactive Survey Game!

A survey questionnaire come to life! Use (nearly) any object to gather helpful data through an interactive, engaging, and fun multiple-choice survey. This project uses the Makey Makey microcontroller in combination with a Raspberry Pi computer to read in… Read more

Prototyping Magnetic Boots!

Walking across large, metal pipes in search of urban adventure, my inner voice joked, “Hey, magnet shoes would be handy right about now.” Well, no arguing with that! Off to build my very own magnetic shoes! This tutorial gives an… Read more

Hazardous Gas Monitor

Build a portable gas monitor to check for dangerous levels of hazardous gases in your home, community, or on the go and prevent your friends from lighting a cigarette during a gasoline fight.* This tutorial shows you how to build a… Read more

Sound Reactive EL Wire Costume

Bring science fiction to life with a personalized light-up outfit! EL wire is a delightfully futuristic-looking luminescent wire that has the added benefit of staying cool, making it ideal for wearable projects. Combining sensors and a microcontroller with EL wire… Read more